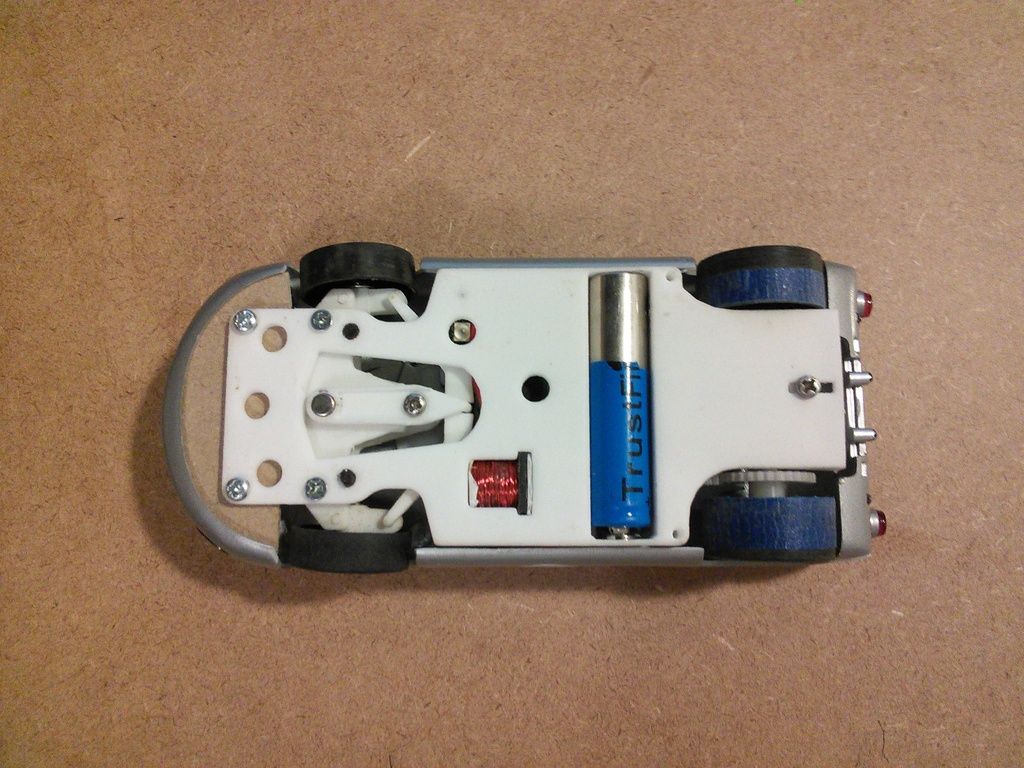

Only unprotected 10440 rechargeable batteries can be used with CK1. There are several ways to connect the battery to the PCB. The best one depends upon the amount of clearance between the end of the battery box and the sides of the body and/or the amount of clearance between the top of the battery box and the cockpit. Every method requires the use of a magnet installed in the battery box near the left rear wheel. This magnet helps to keep the battery from falling out of the chassis. It should be 2.5mm to 3.0mm thick.

Option 1: For narrow bodies with no clearance between the ends of the battery box and the sides of the body

1. Press a 5mm dia x 1.25mm - 1.75mm thick magnet into the hole in the end of the battery box, until it is flush with the outside of the end of the battery box. Apply thin CA glue to the edges of the battery on the outside of the battery box to keep it from sliding out.

2. Press a 5mm x 2.5mm - 3.0mm thick magnet into the hole in the side of the battery box that is near the right rear wheel. This will keep the battery from falling out.

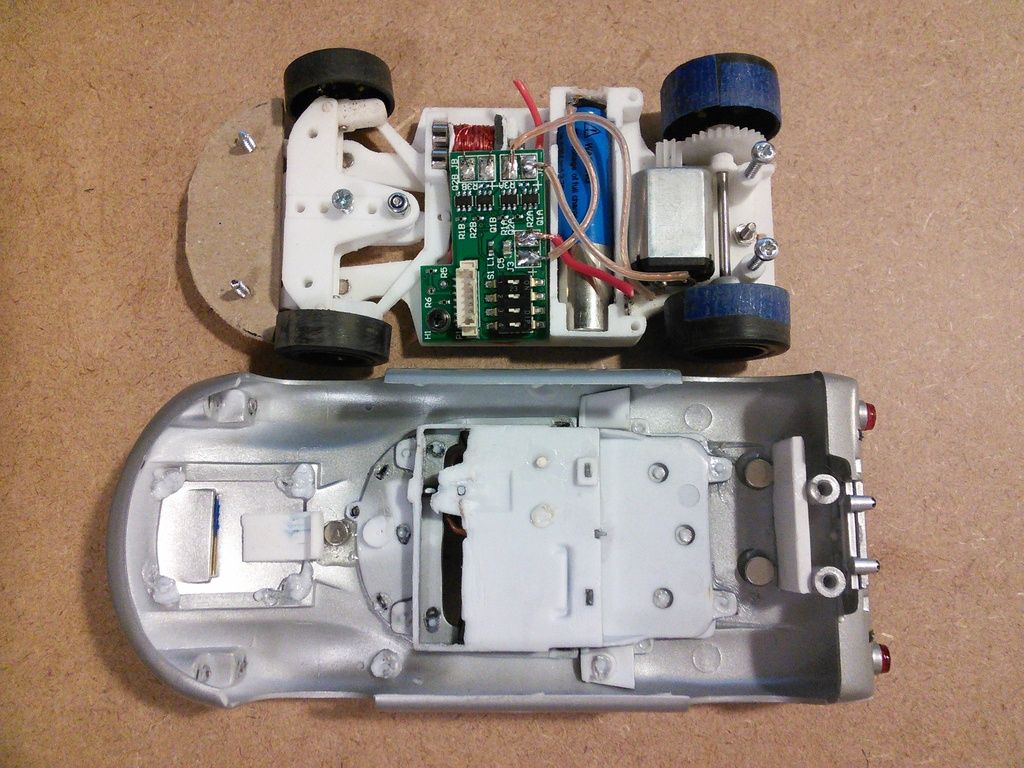

3. If need be, cut 2 thin flexible wires the appropriate length to connect both battery terminals to the PCB as indicated in the photo below.

4. Solder one end of each wire to a piece of steel strip about .01” x .15” x .20”. I recommend using standard lane change plate material for this. Solder the other end of each to the PCB. Do NOT try to solder wire directly to a magnet because excessive heat will destroy the magnet.

5. In the case of the negative (-) battery terminal, attach the wire to the surface of the magnet that is outside the battery box near the left rear wheel.

6. In the case of the positive (+) terminal, attach the wire between the end of the battery and the magnet. This keeps the point of connection inside the battery box. However, it does require a little more care when changing the battery. See photo above.

Option 2: For bodies with plenty of clearance between the ends of the battery box and the sides of the body

Use the same approach as for narrow bodies with the following exceptions:

1. Press a 5mm dia x 3.00mm thick magnet into the hole in the end of the battery box. Do not glue this magnet into place, until you are certain how much clearance you need inside, to change the battery easily.

2. In the case of the positive (+) terminal, attach the wire to the surface of the magnet that is outside the battery box. This keeps the point of connection outside the battery box.

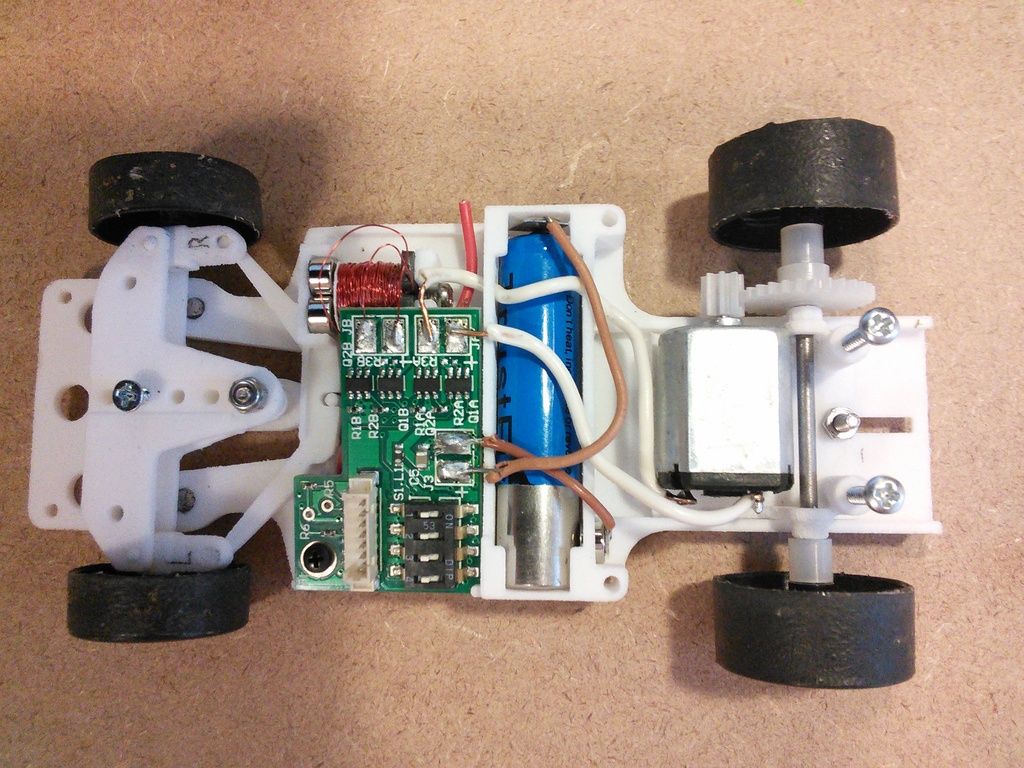

Option 3: For bodies with very little clearance between the top of the battery box and the cockpit

The key to minimizing the problem due to inadequate vertical clearance is to reduce the number of times wires have to cross over the top of the long walls of the battery box, especially the one in front. Also eliminating any wires above the PCB is essential. Use the same approach as for narrow bodies with the following exceptions:

1. Run thin, very flexible wires from the motor to the PCB through both holes in the side of the battery box.

2. Press a 3mm dia x 2mm thick magnet into the hole at the end of the battery box on the left side of the chassis and connect the pos (+) battery terminal here instead of at the other end. Eventually, after some trials, you will probably have to glue this magnet in place with CA glue applied to the outside edges of the magnet.

3. Connect the neg (-) terminal on the right-hand side of the chassis. Now the wires connecting the battery to the PCB, do not have to cross each other and they don’t have to run above the PCB. Just run very flexible wires, inside and along the front wall of the box above the battery, from the battery terminals to the PCB. To do this you will have to drill a hole in both ends of the battery box in the upper corner of the box near the front wall. The diameter of these holes should be slightly larger than the diameter of your wire. Fish your wires through these holes before soldering them to the PCB. You may have to glue these wires in place after installed.

4. Use a 5mm x 3mm magnet magnet for the neg (-) terminal in the end of the battery box, since a thin magnet won’t be strong enough to keep the battery from falling out. Do not glue this magnet in place.

Option 3 does NOT require that insulation be stripped from a portion of the battery near the neg (-) end, since electrical contact is made at each end of the battery. However, you must be careful not to insert the battery the wrong way. Also, after inserting a new battery, you’ll have to squeeze both magnets between your thumb and finger, to make sure both magnets make contact with the ends of the battery. With the small magnet glued in place at one end, and the larger magnet NOT glued in place, this should work.

Please contact me by PM, if you find a mistake in the instructions or have a suggestion for improving them.