Re: Materials, Tools, and Techniques for Outdoor Track

Posted: Mon 2. Mar 2015 02:06

Markus, thank you for sharing your ideas and experience. I'm glad to hear that you have developed a track with cars that have “nearly...perfect conditions”. I assume by “nearly...perfect conditions” you mean that the cars don't loose the wire unless they are driven too fast around corners, cars can navigate turns at realistic or higher scale speeds, cars don't experience front-end shimmy (front wheels dancing) at high speeds, cars have realistic acceleration and traction, and cars can change lanes reliably at medium to high speeds. (There is no need to change lanes at slow speeds in my opinion.) You should be proud of your accomplishment. It's not easy to get great performance from the system and it takes a lot of persistence and work. Congratulations! (Good performance on the other hand is quite easy to achieve with a little guidance from Wes and other members of this forum.)

I believe that my cars and track provide excellent performance with the exception of front-end shimmy at speeds over 165 mph and as a consequences, inconsistent lane changing at those speeds. Top speed is about 200 mph. My cars are unmodified as received from Wes, with the exception that they have .06 mm (.002”) thick tires added, which are made from disposable black nitrile rubber gloves. My track is made per Wes's standard, except that my piano wire is .032” diameter instead of .028”. I have tried your idea of lowering the side magnets, which are located in the chassis between the front wheels, and which repel the steering guide magnet, and thereby help to keep the front wheels pointing straight ahead. This has not helped much. I'll continue to experiment.

I know from Wes and my own experience, that reducing the clearance between the bottom of the guide magnet and the top of the wire helps reduce front-end shimmy. The minimum clearance that one may achieve with good results is primarily dependent upon the maximum thickness of the paint covering the wire and the consistency of the vertical distance from the top of the paint covering the wire to the top of the track surface where the tires actually make contact with the painted track surface. In the case of a track made with slots for the wire, a variation of +/- .003” from flush causes problems. Depressions in the track surface where the tires make contact with the track, which may occur in the case of a baseboard made from foam insulation board, makes matters worse. I suppose that in the case of a perfect track with slots for the wire, one where the top of the wire is perfectly flush with a smooth, flat, and hard baseboard material prior to the last coat of paint and where the last coat of paint or other material covering the track and wire is a uniform 2 mils (.002”) thick, one might be able to operate cars with a static clearance of .004” between the bottom of the guide magnet and the top of the wire, 0.002” for paint and 0.002” for an air space between the magnet and the paint. I think that would be a perfect track for these cars, but which a hobbyist cannot achieve in my opinion. (A typical sheet of computer paper is .0035 to .0040” thick. The radius of my front tires varies by more than 0.001” which necessitates more than 0.001” of air space under the guide magnet.) As I stated yesterday in my post, “I have concluded that the bottom of the guide magnet of my cars is usually running about .005 to 0.010” above the top of the wire, and .002” to .006” above the coating/paint that is covering the wire. That may not be perfect but it's good enough to achieve very good racing performance from my cars and have a blast!

As Wes has told us, and as you have discovered, when we change one thing in the system of track and cars, we often have to change something else, because many inter-related factors affect performance. I still have about 65 feet of track to build and I'm sure that many others will be building tracks in the future. If you, as well as other members, answered the following related questions by posting a reply, the most relevant information for building a track, would be easy for everyone to find. I as well as others, would be very grateful. I have numbered the questions so it will be easy for everyone to number their answers correspondingly.

1. Did you build a track which will always be protected from the weather, such as an indoor track, or did you make an outdoor track, not protected from the weather? If unprotected outside, is it on the ground or on supports of some kind?

2. Is your track permanently located in one place?

3. What did you use as your baseboard material? How thick is it?

4. Did you use steel piano/music wire or thin steel strip/tape? If wire, what diameter and how long are the pieces? If steel strip/tape, how thick and how wide? (Piano wire is also called spring tempered wire, and spring-back wire in some places.)

5. Does the wire or strip/tape have any rust inhibiting coating? If so, what is it and is it effective? (A lot of piano wire is phosphate coated to inhibit corrosion.)

6. Did you glue the wire or strip/tape in a groove/slot in the baseboard or on top of the baseboard?

7. If you cut a slot, what method (or type of tool) did you use and how difficult was it to maintain the correct depth??

8. If you glued the wire on top, what did you use as fill material around the wires to cause the top of the wire to be flush with the track surface where the tires ride?

9. What glue did you use to adhere the wire or strip/tape to the baseboard?

10. Did you put any undercoating (paint) on the baseboard before you attached any wire or strip/tape to the baseboard?

11. Did you apply any paint or other material over the baseboard and wire or strip/tape, after it was attached to the baseboard? Is so, what type of paint/coating? Flat? Glossy? Water based? Oil based? How did you apply it? About how thick is the coating over the wire or strip/tape?

12. What is the shortest radius turn in your track? About how fast can your cars go around that turn. Is that turn banked? If so, about how many degrees? Is it a hairpin turn?

13. Do you have any hills? If so, what is the grade/slope of the steepest? As an example, 1 unit of rise over 10 units of run = 10%. Canton Street in Pittsbugh, PA has a grade of 37%, one of the steepest streets in the world. Can your cars start and stop on your steepest hill?

14. Is your track made of sections which can be put together for racing and taken apart for storage? If so, how do you fasten the sections of track together, and are they placed on a table or similar structure or on a floor or similar relatively smooth surface?

15. Do all of your lane change points in the track incorporate a steel lane change plate, about 0.009” thick x 0.185” wide, such as the type sold by Wes? If not, have you found anything that works better?

16. Have you done anything unusual in building the track, something unique...perhaps something you invented yourself, to create a feature or to deal with specific problems in a part of the track or handle cars that loose the wire? Are you satisfied with the results?

17. Did you modify or change the wheels and/or tires that came with the chassis that was sold by Wes prior to January 2015? If so, what exactly did you do and what effect did it have?

18. Did you make any modifications to the standard chassis, that was sold by Wes prior to January 2015? If so, what exactly did you do and how did it affect the performance of the car?

19. If you were to build another track, what might you do differently?

20. Please add any other question and answer you think might be helpful for other members building tracks.

I will answer all of these questions for my track in my next post. I hope you will also.

I believe that my cars and track provide excellent performance with the exception of front-end shimmy at speeds over 165 mph and as a consequences, inconsistent lane changing at those speeds. Top speed is about 200 mph. My cars are unmodified as received from Wes, with the exception that they have .06 mm (.002”) thick tires added, which are made from disposable black nitrile rubber gloves. My track is made per Wes's standard, except that my piano wire is .032” diameter instead of .028”. I have tried your idea of lowering the side magnets, which are located in the chassis between the front wheels, and which repel the steering guide magnet, and thereby help to keep the front wheels pointing straight ahead. This has not helped much. I'll continue to experiment.

I know from Wes and my own experience, that reducing the clearance between the bottom of the guide magnet and the top of the wire helps reduce front-end shimmy. The minimum clearance that one may achieve with good results is primarily dependent upon the maximum thickness of the paint covering the wire and the consistency of the vertical distance from the top of the paint covering the wire to the top of the track surface where the tires actually make contact with the painted track surface. In the case of a track made with slots for the wire, a variation of +/- .003” from flush causes problems. Depressions in the track surface where the tires make contact with the track, which may occur in the case of a baseboard made from foam insulation board, makes matters worse. I suppose that in the case of a perfect track with slots for the wire, one where the top of the wire is perfectly flush with a smooth, flat, and hard baseboard material prior to the last coat of paint and where the last coat of paint or other material covering the track and wire is a uniform 2 mils (.002”) thick, one might be able to operate cars with a static clearance of .004” between the bottom of the guide magnet and the top of the wire, 0.002” for paint and 0.002” for an air space between the magnet and the paint. I think that would be a perfect track for these cars, but which a hobbyist cannot achieve in my opinion. (A typical sheet of computer paper is .0035 to .0040” thick. The radius of my front tires varies by more than 0.001” which necessitates more than 0.001” of air space under the guide magnet.) As I stated yesterday in my post, “I have concluded that the bottom of the guide magnet of my cars is usually running about .005 to 0.010” above the top of the wire, and .002” to .006” above the coating/paint that is covering the wire. That may not be perfect but it's good enough to achieve very good racing performance from my cars and have a blast!

As Wes has told us, and as you have discovered, when we change one thing in the system of track and cars, we often have to change something else, because many inter-related factors affect performance. I still have about 65 feet of track to build and I'm sure that many others will be building tracks in the future. If you, as well as other members, answered the following related questions by posting a reply, the most relevant information for building a track, would be easy for everyone to find. I as well as others, would be very grateful. I have numbered the questions so it will be easy for everyone to number their answers correspondingly.

1. Did you build a track which will always be protected from the weather, such as an indoor track, or did you make an outdoor track, not protected from the weather? If unprotected outside, is it on the ground or on supports of some kind?

2. Is your track permanently located in one place?

3. What did you use as your baseboard material? How thick is it?

4. Did you use steel piano/music wire or thin steel strip/tape? If wire, what diameter and how long are the pieces? If steel strip/tape, how thick and how wide? (Piano wire is also called spring tempered wire, and spring-back wire in some places.)

5. Does the wire or strip/tape have any rust inhibiting coating? If so, what is it and is it effective? (A lot of piano wire is phosphate coated to inhibit corrosion.)

6. Did you glue the wire or strip/tape in a groove/slot in the baseboard or on top of the baseboard?

7. If you cut a slot, what method (or type of tool) did you use and how difficult was it to maintain the correct depth??

8. If you glued the wire on top, what did you use as fill material around the wires to cause the top of the wire to be flush with the track surface where the tires ride?

9. What glue did you use to adhere the wire or strip/tape to the baseboard?

10. Did you put any undercoating (paint) on the baseboard before you attached any wire or strip/tape to the baseboard?

11. Did you apply any paint or other material over the baseboard and wire or strip/tape, after it was attached to the baseboard? Is so, what type of paint/coating? Flat? Glossy? Water based? Oil based? How did you apply it? About how thick is the coating over the wire or strip/tape?

12. What is the shortest radius turn in your track? About how fast can your cars go around that turn. Is that turn banked? If so, about how many degrees? Is it a hairpin turn?

13. Do you have any hills? If so, what is the grade/slope of the steepest? As an example, 1 unit of rise over 10 units of run = 10%. Canton Street in Pittsbugh, PA has a grade of 37%, one of the steepest streets in the world. Can your cars start and stop on your steepest hill?

14. Is your track made of sections which can be put together for racing and taken apart for storage? If so, how do you fasten the sections of track together, and are they placed on a table or similar structure or on a floor or similar relatively smooth surface?

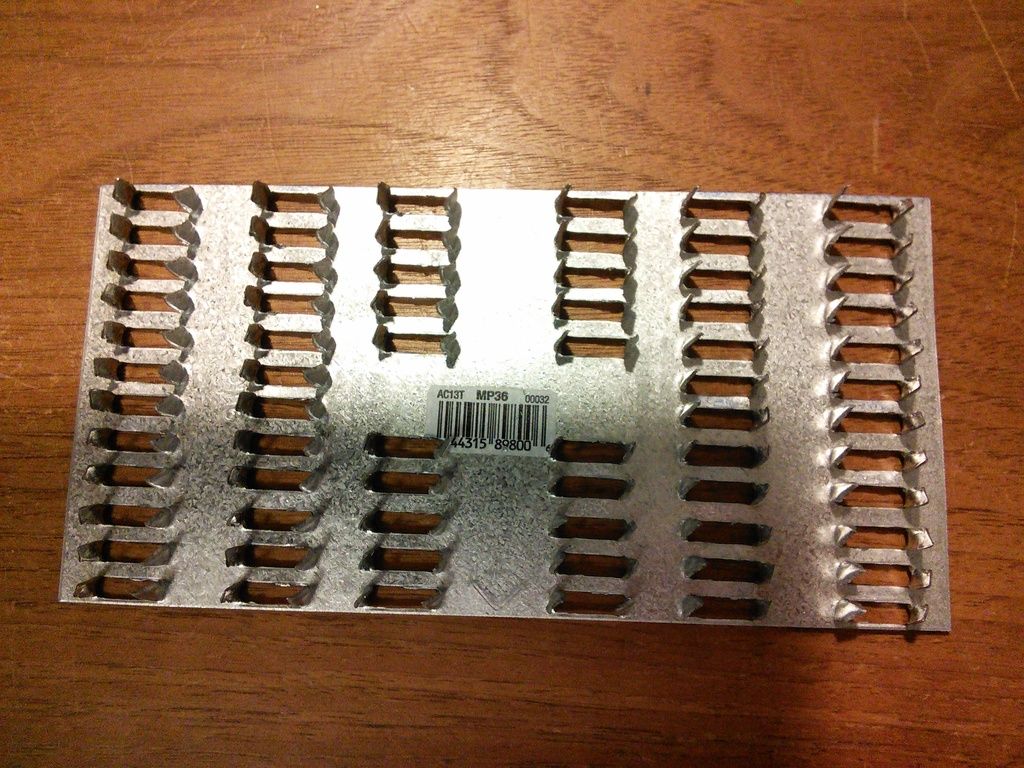

15. Do all of your lane change points in the track incorporate a steel lane change plate, about 0.009” thick x 0.185” wide, such as the type sold by Wes? If not, have you found anything that works better?

16. Have you done anything unusual in building the track, something unique...perhaps something you invented yourself, to create a feature or to deal with specific problems in a part of the track or handle cars that loose the wire? Are you satisfied with the results?

17. Did you modify or change the wheels and/or tires that came with the chassis that was sold by Wes prior to January 2015? If so, what exactly did you do and what effect did it have?

18. Did you make any modifications to the standard chassis, that was sold by Wes prior to January 2015? If so, what exactly did you do and how did it affect the performance of the car?

19. If you were to build another track, what might you do differently?

20. Please add any other question and answer you think might be helpful for other members building tracks.

I will answer all of these questions for my track in my next post. I hope you will also.