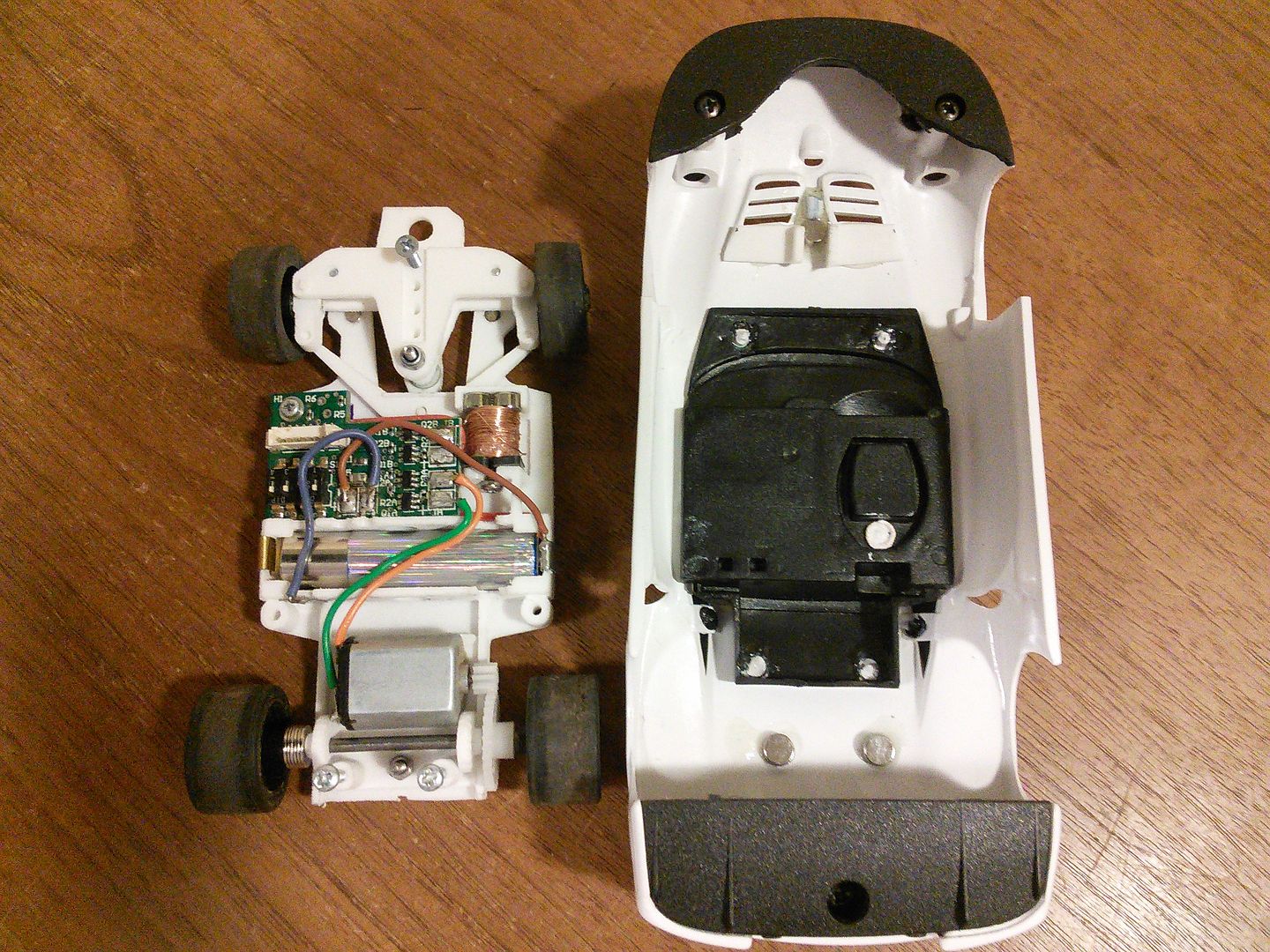

I used 2.5mm x 12mm stainless steel machine screws for front stub axles.

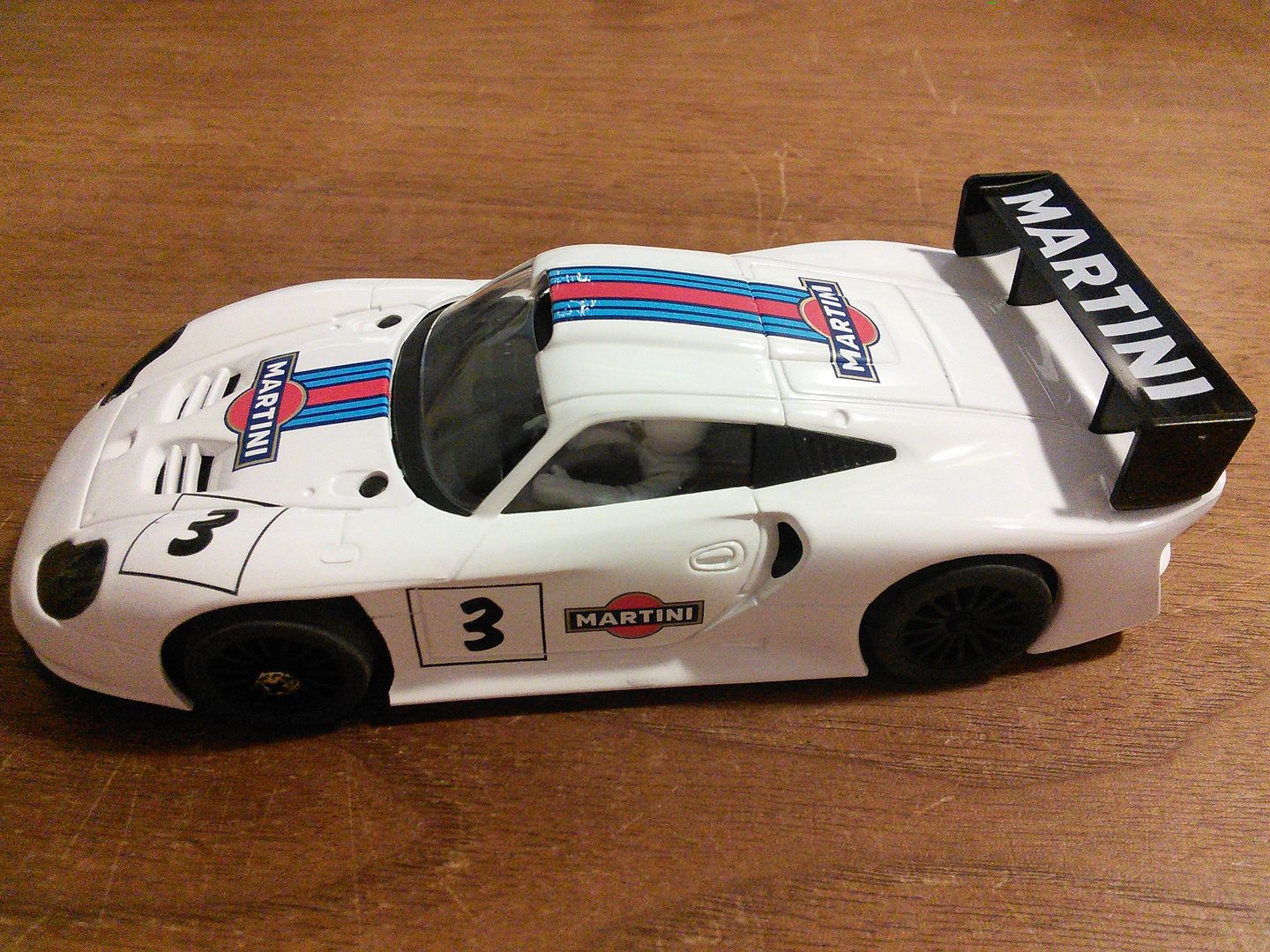

The body by itself weighs 29 grams. The entire car with the battery weighs 83 grams.

The front tires were sanded down so that the diameter on the outside is smaller than on the inside. This causes the tires to ride on the inside edges which reduces frontend shimmy.

I designed the chassis using free 3D modeling software by SpaceClaim called DesignSpark Mechanical. It was printed by Shapeways in NYC using SLS nylon. The frontend of this chassis has 2 degrees of positive toe. Subsequent versions of the chassis have 1 degree of toe in and 2 degrees of negative camber. The negative camber eliminates the need to sand down the outside edges of the tires.

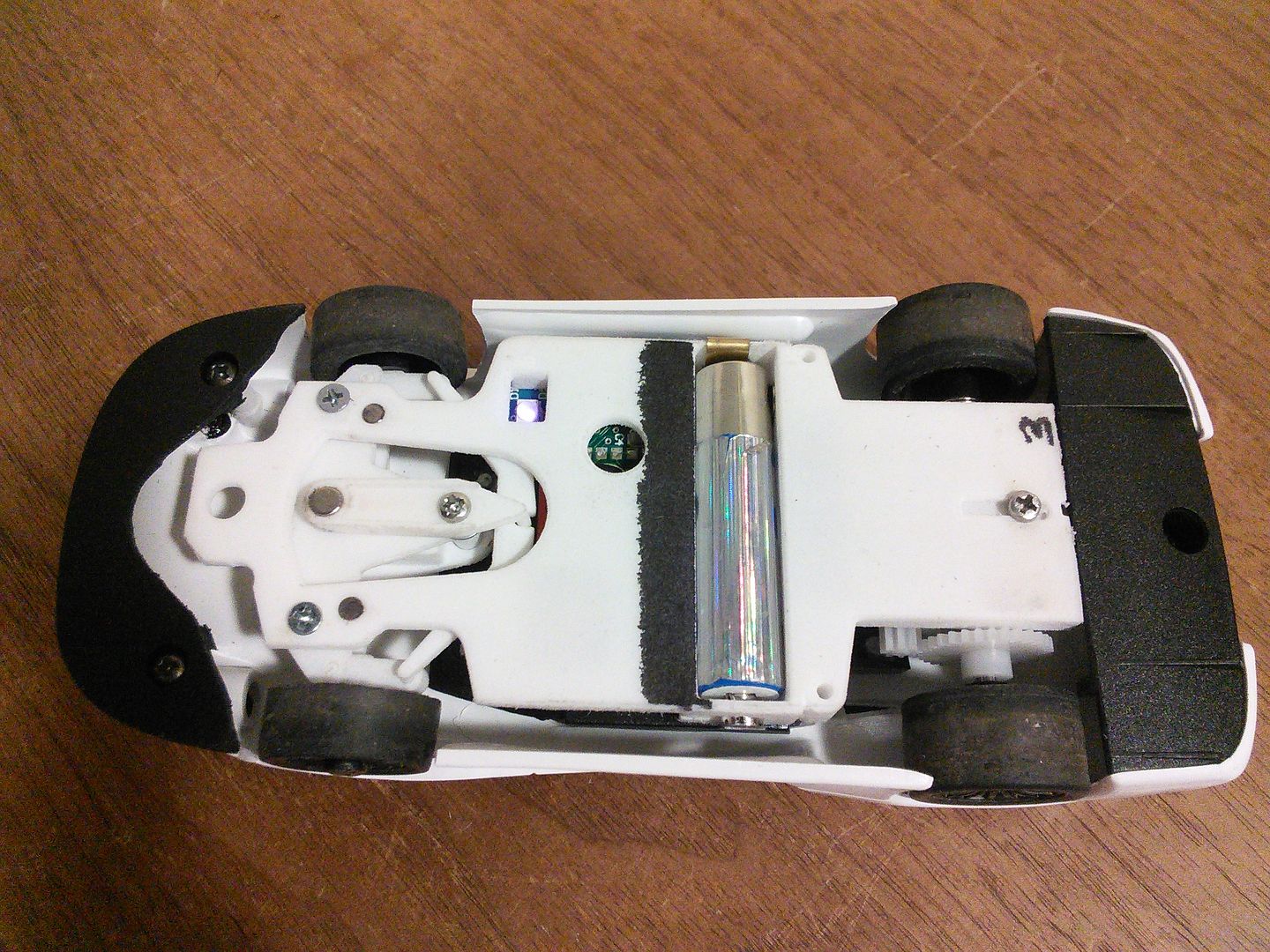

The body is held to the chassis with 3 magnets.

Instead of a bumper attached to the chassis frame, I glued a 3 pieces of plastic around the small magnet which is glued to the underside of the hood in front. The screw in the front/center of the upper suspension plate adheres to this magnet. The 3 pieces of plastic around the magnet prevent the screw, and thus the chassis, from sliding forward, left, or right, relative to the body, upon a crash. This chassis with or without the body, exhibits no front end shimmy.